WHEATON

800.225.1437 (U.S. & Canada Only) | 856.825.1100 | 856.825.1368 (F) |

www.wheaton.comTubular Sample Vials

Serum Vials

> 176

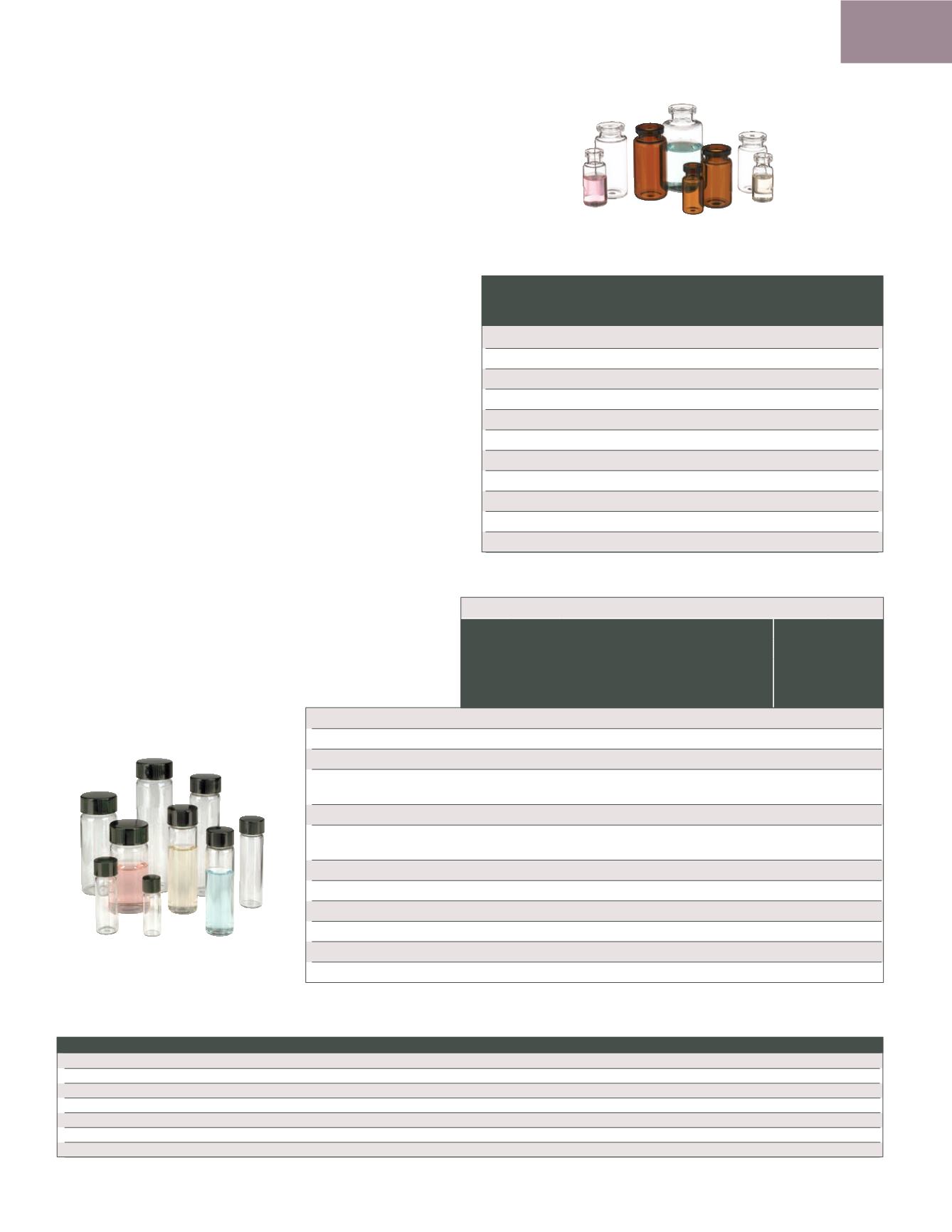

Technical Data, Glass

Table 5. Typical Properties of WHEATON Glass

Borosilicate

Soda-Lime

“180”

“200”

“300”

“320”

“400”

“500”

“800”

“900”

Tubing

Vial

Clear

Tubing

Vial

Clear

Tubing

Vial

Clear

Tubing

Vial

Amber

Molded

Container

Clear

Molded

Container

Amber

Molded

Container

Clear

Molded

Container

Amber

Strain Point °C

510 505 525 510 520 505 510 496

Annealing Point °C

560 560 570 560 560 540 548 536

Softening Point °C

821 820 785 770 735 730 729 713

Linear Coefficient of

Expansion (0-300°C) x 10

-7

33 33 55 55 63 62 88 91

Density g/cm3

2.23 2.22 2.33 2.42 2.44 2.46 2.48 2.50

ASTM E-438 Glass Type

I

I I — — — — —

& Class

A A B — — — — —

USP Powered Glass <660>

Type I Type I Type I Type I Type I Type I Type III Type III

USP Light Transmission <671>

— — — Yes — Yes — Yes

USP Arsenic <211>

Yes Yes Yes Yes Yes Yes Yes Yes

EP Glass Grains (Test B) 3.2.1

Type I Type I Type I Type I Type I Type I Type III Type III

EP Spectral Transmission 3.2.1

— — — Yes — Yes —

Yes

EP Arsenic 3.2.1

Yes Yes Yes Yes Yes Yes Yes Yes

USP= U.S. Pharmacopeia, EP= European Pharmacopeia

Glass Types

The glass products in this catalog are made from many different glass formulations.

Following are brief definitions of these glass types and descriptions of their characteristics.

180 Glass:

An exceptionally clear borosilicate glass of high chemical durability, which has

been especially formulated for the lowest background count. Great care has been taken

to select only those ingredients for the batch that would not cause unwanted background

count or color. Potassium as a separate element has been excluded from the batch to

minimize K40. Special controls assure high quality and batch-to-batch uniformity. This

glass is only available as a tubing vial.

200 Glass:

Also referred to as 33 expansion low extractable borosilicate glass, is a clear

borosilicate glass with exceptional thermal endurance that meets the requirements for

ASTM E-438 Type I, Class A. This glass also meets USP Type I Powdered Glass, USP

Arsenic, EP Type I Glass Grains (Test B) and EP Arsenic as specified in the current revisions

of the U.S. Pharmacopeia and European Pharmacopeia. Most of our laboratory products

are made from this type of glass.

300 Glass:

A chemically resistant clear borosilicate glass that meets the requirements

for ASTM E-438 Type I, Class B. This glass also meets USP Type I Powdered Glass, USP

Arsenic, EP Type I Glass Grains (Test B), EP Arsenic as specified in the current revisions of

the U.S. Pharmacopeia and European Pharmacopeia.

320 Glass:

A similar composition to 300 Glass except amber color for light sensitive

applications. Meets UV light protection limits as specified in the current revisions of the

U.S. Pharmacopeia and European Pharmacopeia.

400 Glass:

A clear borosilicate glass that falls well within the limits for USP Type I

Powdered Glass, USP Arsenic, EP Type I Glass Grains (Test B) and EP Arsenic as specified

in the current revisions of the U.S. Pharmacopeia and European Pharmacopeia.

500 Glass:

Similar to the 400 Glass formulations except amber color for light sensitive

applications. Meets UV light protection limits as specified in the current revisions of the

U.S. Pharmacopeia and European Pharmacopeia.

800 Glass:

A superior soda-lime clear glass that meets the requirements for USP Type III

Powdered Glass, USP Arsenic, EP Type III Glass Grains (Test B) and EP Arsenic as specified

in the current revisions of the U.S. Pharmacopeia and European Pharmacopeia.

900 Glass:

Similar in formulation to 800 Glass except amber color for light sensitive

applications. Meets UV light protection limits as specified in the current revisions of the

U.S. Pharmacopeia and European Pharmacopeia.

Table 6. Typical Elemental Extraction Data of Some Glass Types (ppm)

USP Glass Type

Si Al Na K Ca Mg Fe Ba Zn

Ti

Type I Clear - Molded 1.3 <0.006 0.26 0.05 <0.02 <0.02 <0.015 <0.008 0.14 <0.005

Type III Clear - Molded 26 0.17 9.1 0.18 3.6

0.20 <0.01 <0.008 0.07 <0.005

Type I Amber - Molded 2.4

0.06 0.71 0.1 <0.02 <0.02 <0.015 <0.008 0.21

<0.005

Type III Amber - Molded 22 0.16 9.3 <0.03 3.4 0.23 0.016 <0.008 0.03

<0.005

Type I Clear - Tubular 4.8 <0.01 1.1 <0.03 0.13

0.07

<0.012 <0.008

<0.01 <0.005

Type I Amber - Tubular 7.4 0.17

1.8

0.45 <0.02

<0.02

<0.015 <0.008 0.23 <0.005

Blank- PE <0.05 <0.006 <0.01 0.048 <0.02 <0.02 <0.015 <0.08 <0.006 <0.005

Results after autoclave at 121°C for 60 minutes - high purity water in 20mL containers

Table 4. Typical Composition (%) of Some Glass Containers

“180” “200” “300” “320” “400” “500” “800” “900”

Forming

Tubing

Tubing Tubing Tubing Molded Molded Molded Molded

Process

Vial

Vial

Vial

Vial

Container Container Container Container

Si0

2

81

81

72

70

69 65.5 73

73

Al

2

O

3

2

2

7

6

5.5

6

2

2

Na

2

O+K

2

O

4

4

9

8

10

9

14 14.2

CaO+MgO

<0.2 <0.2 1

0.5 1.5 0.5 10.5 10

B

2

O

3

13

13

12

7

11

9

— 0.5

Fe

2

O

3

<0.1 <0.1 <0.1 1.5 <0.1

1 <0.05 0.3

BaO

— — <0.1

2

2.5 1.5

— —

ZnO

— — — — 0.5 0.5

— —

MnO

2

— — — — — 7

— —

TiO

2

— — — 5

— — — —

SO

3

— — — — — — 0.2

—

Glass Type