WHEATON

800.225.1437 (U.S. & Canada Only) | 856.825.1100 | 856.825.1368 (F) |

www.wheaton.comFactors for the Selection of a Plastic Container

Plastic containers have been developed for a variety of applications across many different industries over the years. There are many different types of polymers used in the creation of

these containers to help fill the demands for the various applications. Polymers offer a variety of properties, each having different levels of importance with different users depending on

the application. Some users may have flexibility within their product formula or filling process thus focus on economical containers while others may need containers that are stronger,

autoclavable, transparent, sterilized, etc.; therefore requiring more specifications. WHEATON can help with polymer selection through comprehension of the customer’s product, goals, and

adaptability. Several questions should be posed to gather this understanding.

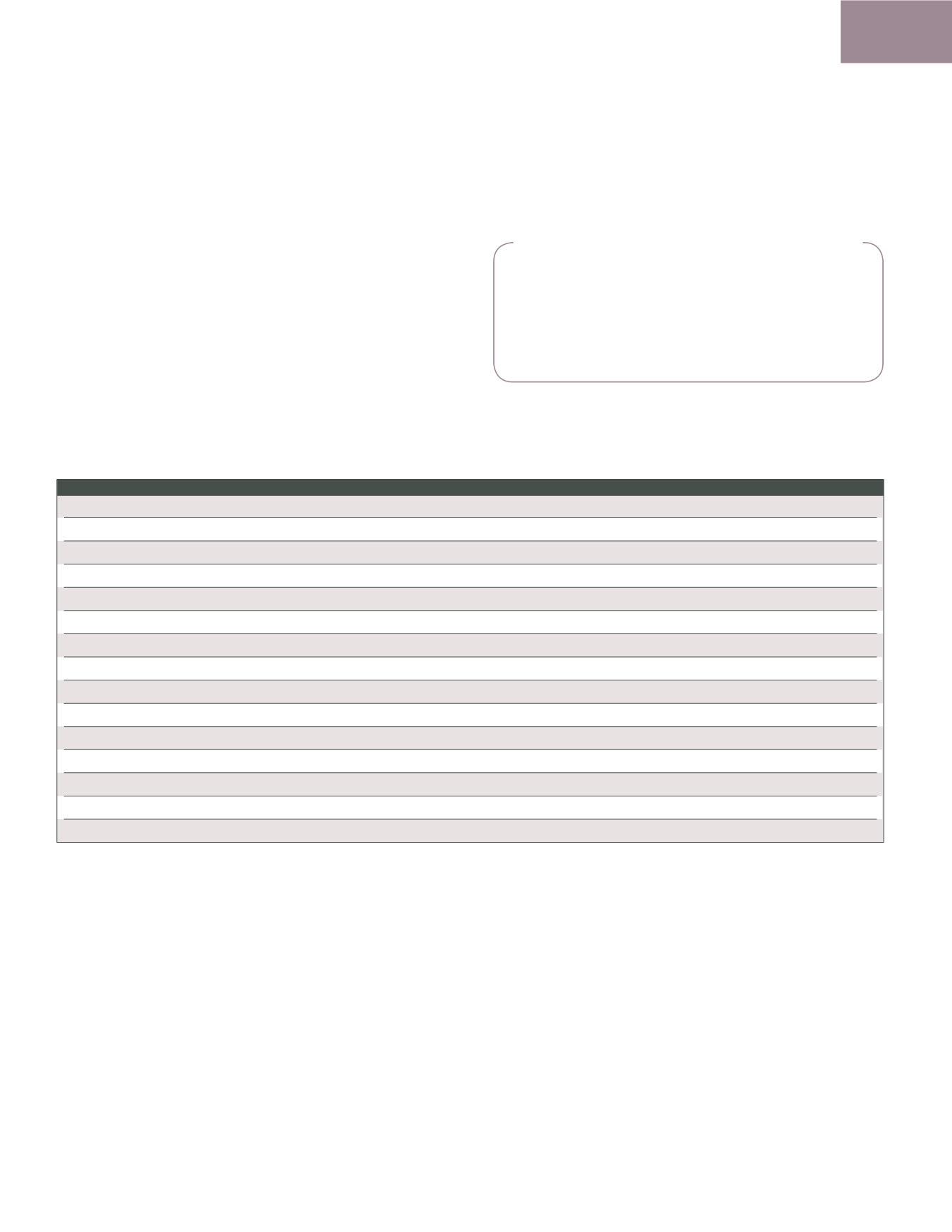

Table 10. Packageability of Plastic Containers

Requirement

PC

PE

PET

PETG

PP

PS

PVC

Lightweight

6

2

5

5

1

3

6

Clarity

1

3

1

1

2

1

1

Toughness

3

1

2

1

3

9

8

Water Adsorption

6

2

3

3

2

4

2

Water Vapor Permeability

6

2

5

4

2

5

4

CO

2

Permeability

7

6

2

3

5

9

3

O

2

Permeability

7

7

2

3

6

8

2

Resistance: Acids

4

2

4

4

2

4

2

Resistance: Alkalis

7

2

5

5

2

2

2

Resistance: Oils

4

4

2

2

3

4

2

Resistance: Solvents

3

3

2

2

3

6

4

Resistance: High Humidity

6

1

1

1

1

1

1

Resistance: Sunlight

4

4

1

2

4

5

5

Resistance: Heat (hot fill)

1

3

1

1

2

5

1

Resistance: Cold

1

1

2

2

4

5

9

This chart is a generalization to aid in selection; there are many forms, thicknesses and various copolymers and additives available. The lower the number, the better the property.

1=Excellent; 9=Poor. (PE Properties are similar for HDPE & LDPE.)

■

What is the container size and physical design. Narrow mouth vs. wide mouth, tall

vs. short, etc.?

■

Must the package be transparent, translucent, opaque or colored for either

marketing or light protection?

■

Are there specific shipment and storage conditions such as refrigeration, freezing,

exclusion of light, etc.?

■

Are there governmental regulations pertaining to the product?

■

How is the product going to be dispensed by the user?

■

Have any tests been run in plastic? Were they unsuccessful and why? What type

of plastics?

Some Examples Include:

> 184

Technical Data, Plastic

These include:

■

Permeation / Barrier

■

Sorption Characteristics

■

Chemical Resistance

■

Stress Crack Resistance

■

Rigidity / Flexibility

■

Impact Resistance

■

Sterilizability

■

Recyclability

■

Temperature Resistance

■

Mold Release

Many Things Govern Polymer Suitability for Package Use