WHEATON

800.225.1437 (U.S. & Canada Only) | 856.825.1100 | 856.825.1368 (F) |

www.wheaton.comElectron Beam (E-Beam) Radiation

An E-beam radiation sterilization facility consists of a protective maze built around an

E-beam generator. The E-beam generator delivers a high dose of electrons focused in

a narrow beam at the items to be sterilized. After exposure, ware is conveyed from the

maze.

A radiation dose sufficient to kill bacteria and spores is about 2.5 MRads. To minimize

costs and attain sterilization, bioburden is determined and the minimum dosage plus a

safety factor is selected.

Electrons from the E-beam generator have limited penetrating power (a 10-MeV

E-beam will penetrate only about 5 cm or 2 inches of a unit-density material). Thus, a

limited number of parts can be packed together for sterilization. The dosage reaching

the center of a ware multi-pack is validated. Higher dosages will occur at the outside

edges of ware multi-packs.

Usually, empty packaging components are sterilized via E-beam. Since effects are

cumulative, twice the normal dose is sometimes examined to insure minimal problems.

Listed below are thermoplastic materials that are recognized as capable of being

electron beam radiation sterilized, although tests should always be run on plastic ware

to determine suitability for a given sterilization method:

■

Low Density Polyethylene

■

Linear Low Density Polyethylene

■

High Density Polyethylene (those containing phosphite stabilizers

may yellow)

■

Polyethylene Terephthalate

■

Polystyrene

■

Polycarbonate

■

Nylon

■

Cyclic Olefin Copolymers (a newly emerging group of polymers)

■

Polyethylene Naphthalate (a newly emerging group of polymer)

Problems can occur when E-beam sterilizing polyvinyl chloride (PVC) or fluoropolymers

(PTFE, etc.)

Important Note About Polypropylene E-Beam Sterilization

Normal PP grades yellow noticeably and exhibit long term embrittlement when sterilized

via E-Beam. Special PP grades, having special stabilizers, are available for E-beam

sterilization. Also, if ware is to be colored, then the concentrate carrier should be a

radiation resistant grade of PP. PP copolymers are more radiation resistant than PP

homopolymers. Tests should always be run on plastic ware to determine suitability for

a given sterilization method.

DISCLAIMER: The data and information contained herein are limited to

illustrative examples that are based on limited testing procedures. However,

due to variable conditions of use and methods processing, NO GUARANTEES OR

WARRANTIES ARE EXPRESSED OR IMPLIED INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. WHEATON

does not recommend any use that infringes patents. This data and information,

and the products and processes described, are subject to change at any time

without notice. Please contact your WHEATON representative with your specific

packaging needs.

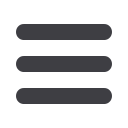

Resin Identification Codes

WHEATON follows the Society of the Plastics Industry (SPI) guidelines for marking plastic

containers with the appropriate resin identification code numbers as shown below:

WHEATON mold-marks our containers on the bottom with the appropriate resin

identification code. These codes are to assist in identifying material used to manufacture

ware to aid in recycling efforts.

1

=

PETE

(polyethylene terephthalate) (PET)

2

=

HDPE

(high density polyethylene)

3

=

V

(vinyl / polyvinyl chloride) (PVC)

4

=

LDPE

(low density polyethylene)

5

=

PP

(polypropylene)

6

=

PS

(polystyrene)

7

= Other

PET Media Bottle

> 188

Technical Data, Plastic

PETE HDPE V LDPE

PP

PS

OTHER