For ordering information see inside back cover

5

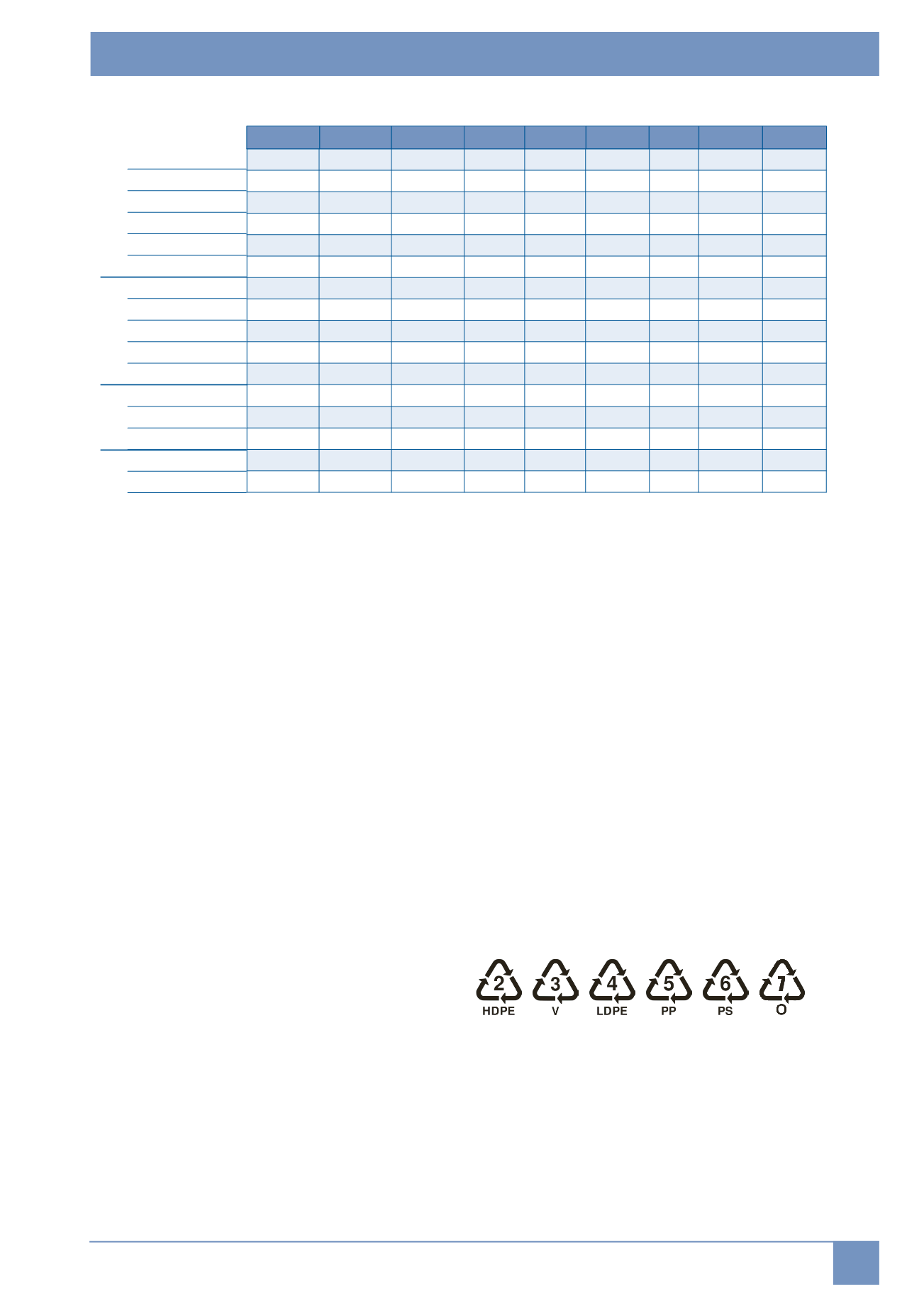

Physical properties of plastics

Food Contact/Animal Derivative Statement

We can confirm that, with respect to the contact of plastic materials

with foodstuffs, our products, where indicated in the catalogue,

comply with one, or both, of the following:

European Regulations (EU) No 10/2011 up to (EU) No 2015/174

relating to plastic materials and articles intended to come into

contact with foodstuffs.

Code of Federal Regulation (CRF), Title 21, Food and Drug

Administration (FDA), Part 177.1520 “Olefin Polymers” , (a) 2)(i) and

(c) 2.1 and 2.2.

We can confirm that in respect to Bovine Spongiform Encephalopathy

(BSE) / Transmissible Spongiform Encephalopathy (TSE), that our

suppliers do not use tallow derived from animal sources in the

manufacture of our products.

Please contact us if you require further information. It is the

responsibility of the user to ensure that the products are suitable for

their intended use.

REACH

EU Regulation 1907/2006/EC including amendments

Regulation EC no. 1907/2006 of the European Parliament and of the

council concerning the Registration, Evaluation, Authorisation and

restriction of CHemicals (REACH) is continually being reviewed and

updates implemented.

After consultation with the UK Health and Safety Executive (HSE) and

Smithers REACH Services (SRS), we are deemed to be a ‘Distributor

of Articles’ (Finished Products) for laboratory products.

Laboratory Plastics (Azlon

®

)

The laboratory plastics we supply are deemed as articles under

REACH and therefore require no (Pre-) registration as there is ‘no

intended release of chemicals from these products’. Azlon products,

to the best of our knowledge and that of our suppliers, do not

contain SVHC’s above thresholds of 0.1% on a weight/ weight basis.

Lipsol

®

Detergent

We are in constant communication with the manufacturers of

Lipsol® to ensure that any relevant REACH (Pre) registration

requirements are met. We confirm that Lipsol® does not contain any

SVHCs above the threshold of 0.1% on a weight/weight basis and is

compliant with REACH.

Recycling plastics

Although our products are designed for the reusable market you

may wish to dispose of them at some point. Therefore here is some

advice on recycling of our plastics.

Recycling involves the segregation of plastic products by specific

resin types ready for the process of converting them into new raw

materials for use in other products.

In order to assist with this segregation, the Society of the Plastics

Industry (SPI) had adopted a classification system to identify the

seven main types of plastic where each resin is assigned a number.

A large proportion of our products also have the following SPI code

permanently moulded into them: -

The seventh classification, or “other” denotes that the product is

either not of the preceding plastics or it is a mixture.

We do not currently supply any products made from PET.

Before recycling any items, please consider the environment and

further handling. All items should be washed, cleaned and/or

disinfected prior to disposal.

Max usage Temp. ºC

Min usage Temp. ºC

Transparency

Flexibility

Specific Gravity

Microwaveable

Autoclavable

Gas

Dry Heat

Radiation (Gamma)

Disinfection

N

2

O

2

CO

2

Water Absorbtion (%)

Cytotoxic

LDPE

HDPE

PP

PMP (TPX)

PC

PS PMMA PTFE

PBT

80

120†

135

145

135

90

50

260

150

-50

-100

-20††

-180

-135

-40

-60

-200

-40

Translucent

Translucent

Translucent

Clear

Clear

Clear

Clear

Opaque

Opaque

Flexible

Rigid

Rigid

Rigid

Rigid

Rigid

Rigid

Rigid

Rigid

0.92

0.95

0.9

0.83

1.2

1.05

1.2

2.2

1.31

Yes

No

Yes

Yes

Marginal

No

No

Yes

No

No

No

Yes

Yes

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

No

No

No

Yes

No

No

No

Yes

No

Yes

Yes

No

No

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Some

Some

Yes

Yes

180

42

48

8,000

50

25

3

Unknown Unknown

500

185

240

32,000

300

400

12

308

Unknown

2,700

580

800

115,000 1,075

1,500

68 Unknown Unknown

<0.01

<0.03

<0.2

0.01

0.35

0.05

0.35

<0.01 Unknown

No

No

No

No

No

No

No

No

Unknown

Sterilisation

Permeability*

Food Contact

* Permeability (cc-mm/m

2

-24hr.Bar).

† Polymer may be malleable at temperatures above 80ºC if the product is under structural stress.

†† Material may become brittle at low temperatures.