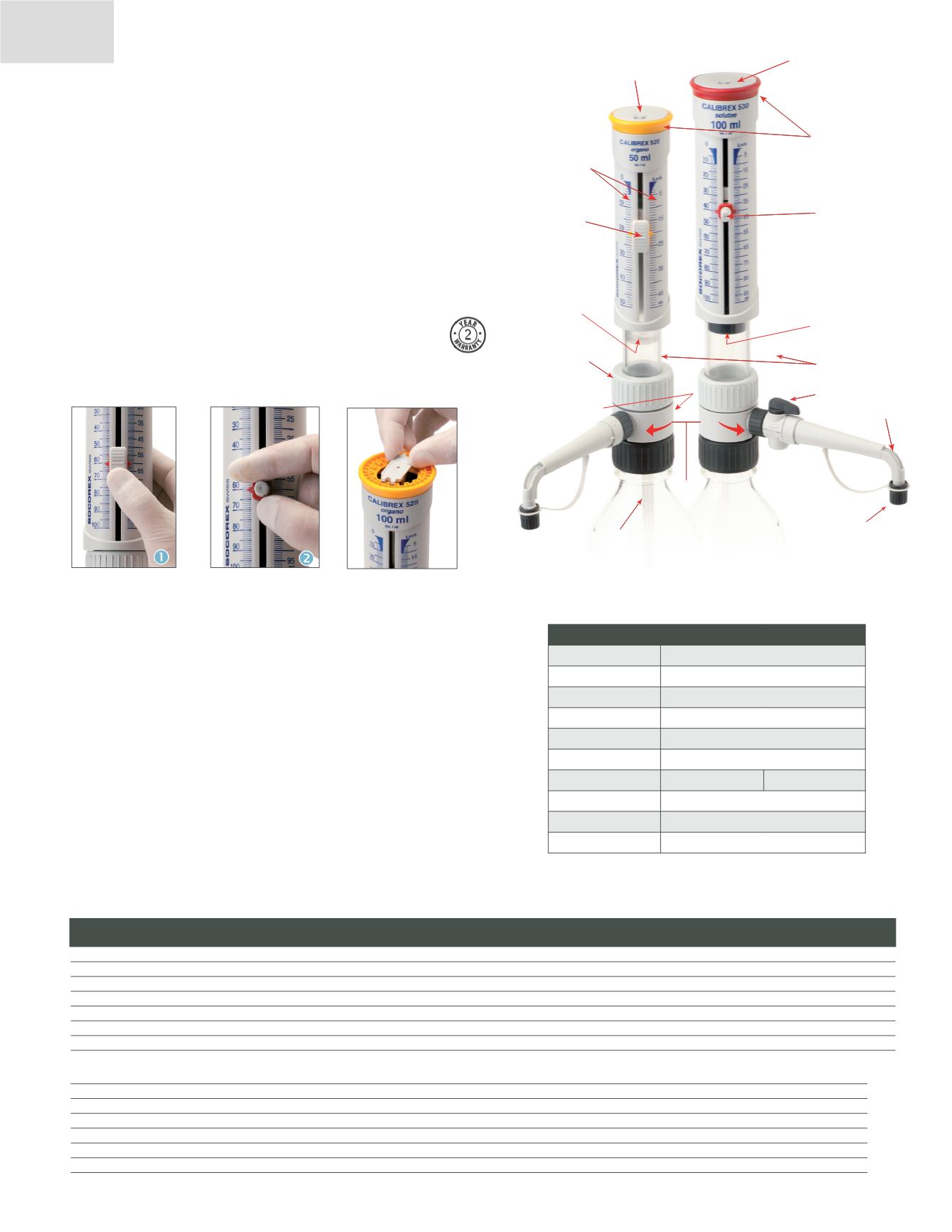

Integrated calibration key under cap

Dual graduation

Volume adjustment

sliding curser

Ground glass plunger

Color coding by model

Liquid viewing window

Screw-locking stopper

360° rotation

on bottle

FEP feed tubing

Disassembling nut,

no tool needed

Air inlet, connection

for filter

Transparent sleeve

PFA coated plunger

Screw-type volume

adjustment button

(interchangeable, as

alternative)

Flow control stopcock

Calibration safety seal sticker

Liquid Handling

525 / 530

2.5 - 25mL

5 - 50mL

10 - 100mL

> 135

Calibrex

™

organo

525 /

solutae

530 Bottle Top Dispensers

This new generation of Socorex

®

Bottle Top Dispensers is intended for the safe and

reproducible liquid distribution of volumes up to 25, 50 and 100mL. The Calibrex

™

organo

525 includes a ground glass plunger, best suited for organics, non-crystallizing acid and base

solutions. The Calibrex

™

solutae 530 has a PFA coated plunger preventing the plunger and

barrel from seizing together. This enables trouble free distribution of salt solutions, weak and

strong acids, as well as bases.

Product Advantages

■

Selection between organo and solutae models for

best chemical resistance

■

Permanent fluid path visibility

■

Integrated calibration system

■

Choice of adjustment button with each unit

■

Long lasting performance stability

■

Autoclavable at 121°C / 250°F fully assembled

■

Two year warranty

Choice of Setting Buttons

Spring loaded sliding cursor

softly moves up and down scale and

precisely stops at desired graduation. Alternative classical screw button

supplied with each dispenser for easy exchange

.

Color Coding

Yellow for

organo

model best suited for organics, non-crystallizing acid and

base solutions. Red for s

olutae

model enabling trouble-free distribution of

salt solutions, weak and strong acids, as well as bases.

Material Selection

Parts in contact with liquid flow are chemically inert, providing for

stability and long instrument life.

Parts

525

organo

530

solutae

Feed Tube

FEP

Valve

Ceramic

Valve Balls

Ceramic

Valve Springs

Platinium-iridium

Valve Plate

PTFE

Barrel

Borosilicate glass

Plunger

Ground glass

PFA coated glass

Body

ETFE

Delivery Jet

FEP/ PCTFE

Stopper

ETFE

Easy in-lab Calibration

Mechanism with integrated key located under plunger cap. Engraved

instructions for fast and correct setting. Access protected by seal sticker.

For Chemical Compatibility see page 137.

Performance and ordering information – Calibrex

™

525 and 530

Supplied with 45 mm base thread, 120mm delivery jet and stopper, 350mm feed tube, alternative screw-type volume setting button, three bottle neck adapters (32, 38 and 40mm), QC

certificate and operating instructions.

Cat. No.

Inaccuracy (E%)

Imprecision (CV%)

525

organo

530

solutae

Volume

Division

Min. Vol.

Mid. Vol.

Max. Vol.

Min. Vol.

Mid. Vol.

Max. Vol.

W845000

W845016

0.1 - 1mL

0.02mL

< ± 3.0 % < ± 1.8 % < ± 0.6 %

< 1.2 % < 0.70 % < 0.17 %

W845002

W845018

0.25 - 2.5mL

0.05mL

< ± 2.7 % < ± 1.6 % < ± 0.6 %

< 0.9 % < 0.55 % < 0.17 %

W845004

W845020

0.5 - 5mL

0.1mL

< ± 2.0 % < ± 1.3 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W845006

W845022

1 - 10mL

0.2mL

< ± 1.5 % < ± 1.2 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W844090 W8441022.5 - 25mL

0.5mL

< ± 1.5 % < ± 1.1 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W844092 W8441045 - 50mL

1.0mL

< ± 1.5 % < ± 1.1 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W844094 W84410610 - 100mL

1.0mL

< ± 1.5 % < ± 1.1 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

With Flow Control Stopcock

W845008

W845024

0.1 - 1mL

0.02mL

< ± 3.0 % < ± 1.8 % < ± 0.6 %

< 1.2 % < 0.70 % < 0.17 %

W845010

W845026

0.25 - 2.5mL

0.05mL

< ± 2.7 % < ± 1.6 % < ± 0.6 %

< 0.9 % < 0.55 % < 0.17 %

W845012

W845028

0.5 - 5mL

0.1mL

< ± 2.0 % < ± 1.3 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W845014

W845030

1 - 10mL

0.2mL

< ± 1.5 % < ± 1.2 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W844096

W844108

2.5 - 25mL

0.5mL

< ± 1.5 % < ± 1.1 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W844098

W844110

5 - 50mL

1.0mL

< ± 1.5 % < ± 1.1 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

W844100

W844112

10 - 100mL

1.0mL

< ± 1.5 % < ± 1.1 % < ± 0.6 %

< 0.5 % < 0.35 % < 0.10 %

*Performance values obtained by a smooth and steady pace movement, with bidest. water at constant temperature (± 0.5°C) comprised between 20°C and 25°C, according to EN ISO 8655. Omission to

untighten connecting body ring before autoclaving, and/or over-tightening ring when dispensing, may reduce performance.