WHEATON

800.225.1437 (U.S. & Canada Only) | 856.825.1100 | 856.825.1368 (F) |

www.wheaton.comChemical Compatibility

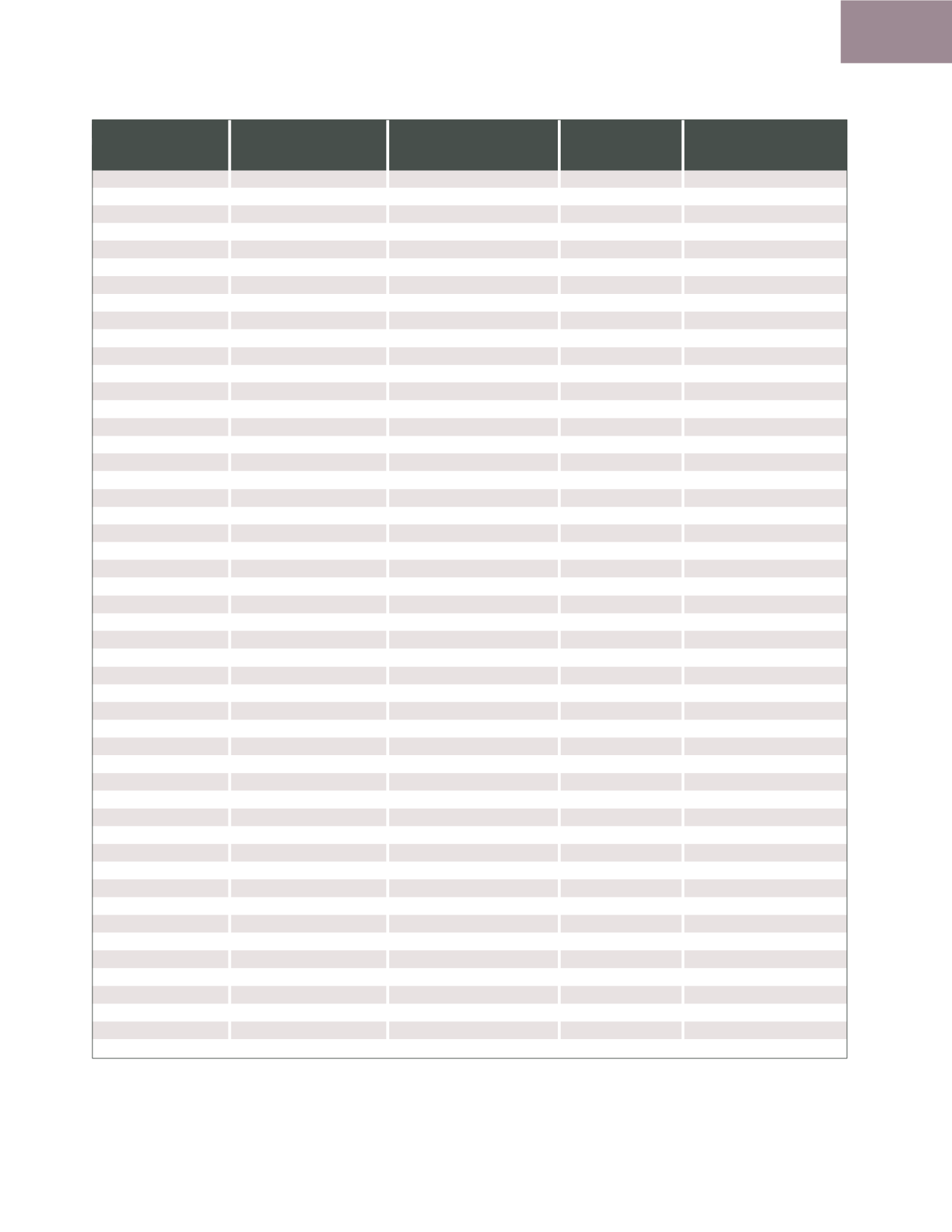

Container Materials

Closure Liner Materials

Closure Materials

Septa, Stopper & Tubing Materials

Poly-

Butyl

Natural

Chemical

Glass HDPE LDPE PC PET PETG PP Al Foil

LDPE Vinyl

PTFE SBR Silicone

PBT Phenolic PP Urea

Rubber FKM Rubber PTFE Silicone TPE

Acetic acid, Glacial

A A B C A C A A B B A C B

C A A D

B D B A B B

Acetone

A D D D C D B A D D A D B

D A B A

B D B A B D

Acetonitrile

A A A D B C A A A D A B D

– A A –

D D D A D D

Acrylonitrile

A A A D B – B B A D A C D

– D B –

D D D A D –

Ammonium Sulfide

A A A D – – A D A A A B A

– A A C

A C A A A B

Benzene

A D D D C D D B D D A D D

A A D A

D A D A D D

Bleach

A A B B C C B D B A A D B

C D B –

A A D A B A

Boric Acid

A A A A A A A D A A A A A

A B A –

A A A A A B

Carbonic Acid

A A A A – A A B A A A B A

B – A –

A A A A A D

Chlorobenzene

A C D D B C C A D D A D D

B A C B

D A D A D D

Chloroform

A C C D D D D A C D A D D

D A D A

D A D A D D

Dichloromethane (DCM)

A C D D D D C D D D A D D

D C C B

D B D A D D

Diethylamine

A C D D – – B A D D A B B

– – B –

B C B A B –

Dimethyl Formamide (DMF)

A A A D B C A A A D A D B

C A A –

D D D A B C

Dimethyl Sulfoxide (DMSO)

A A A D B C A A A D A D D

C – A –

D D D A D –

Dioxane

A B B D A A D D B D A D D

B A D –

B D D A D –

Ether

A C D D A A D B D D A D D

A B D B

D C D A D D

Ethyl Acetate

A B B D B C C B B D A D C

C A C B

C D D A C D

Ethyl Alcohol

A A A A A A A B A B A A B

A B A A

A A A A B B

Ethylene Glycol

A A A A A A A B A A A A A

A B A B

A A A A A B

Formaldehyde

A A A A B A A A A C A B B

A B A A

A C C A B A

Formic Acid 50%

A A B B – – A C B B A B C

A C A D

A C B A C B

Gasoline

A C D C B B C A D D A D D

A B C A

D A D A D D

Glycerine

A A A A – A A A A C A A B

A A A –

A A A A B B

Heptane

A C D B B – C A D C A D D

A A C A

D A D A D C

Hexane

A B D C C B B A D D A D D

A B B –

D A D A D B

Hydrochloric Acid (HCL) 50%

A A A D B C A D A B A D D

C A A D

A A B A D B

Hydrofluoric Acid (HF) 50%

D A A D C D A D A C A D D

C D A D

C A C A D A

Hydrogen Peroxide 50%

B A A A B B A A A C A C B

B D A D

B A B A B B

Iodine

A C D C A – C A D C A B A

D -

C –

B A D A A D

Isopropyl Alcohol

A A A A A A A A A B A B A

A A A –

A A A A A B

Methyl Alcohol

A A A B B A A A A C A A A

B B A A

A D A A A A

Methyl Ethyl Ketone (MEK)

A D D D B C B A D D A D D

C A B –

A D D A D B

Methylene Chloride

A C D D D D C D D D A D D

D C C B

D B D A D D

Nitric Acid 50%

A C B B C B C D B B A D D

C B C D

C B C A D B

Pentane

A C C A – – D A C D A D D

B – D –

D A D A D B

Perchloric Acid 50%

B B B D B C B D B D B D D

– – B –

B A D B D A

Phenol 50%

A D D D D D D A D C A D D

D A D –

D A D A D D

Phosphoric Acid 50%

A A A A B – A B A B A D D

B B A D

B A D A D A

Picric Acid

A D D D B – D A D D A B D

D A D D

B A B A D D

Potassium Hydroxide

D A A D D D A D A A A B C

C D A –

A B B A C A

Sodium Hydroxide 50%

D A B D D C A D B C A A B

C D A C

A B A A B C

Sodium Peroxide

A B B A – – B C B A A B D

B B B D

A A B A D A

Sodium Thiosulfate

A A A B B – A A A A A B A

B A A B

A A B A A –

Sulfuric Acid 50%

A A A B B C B C A C A D D

B C B D

D A D A D A

Tetrahydrofuran (THF)

A C C D B D B A C D A D D

D A B –

C D D A D D

Toluene

A C C D C C C A C C A D D

D A C –

D B D A D D

Trifluoroacetic Acid (TFA) 50% A A A D B – A B A A A B D

– – A –

B C B A D –

Vegetable Oil

A B B A A A A A B A A D A

A A A A

C A D A A –

Xylene

A C D D C – D A D D A D D

C A D B

D A D A D D

(Tests conducted at room temp)

A

- Resistant

B

- Limited Resistance

C

- Poor Resistance

D

- Not Resistant

—

- Unknown

Al Foil

... aluminum foil

FMK

... fluoroelastomer

HDPE

... high density polyethylene

LDPE

... low density polyethylene

PBT

... polybutylene terephthalate

PC

... polycarbonate

PET

... poyethylene terephthalate

PETG

... polyethylene terephthalate g copolymer

PP

... polypropylene

PTFE

... polytetrafluoroethylene

SBR

... styrene butadiene rubber

TPE

... thermoplastic Elastomer, C-Flex

Although the information in this chart was acquired from reputable sources, it should only be used as a guide in selecting a container and closure system. Because so many factors can affect the chemical

resistance of a material, in-house testing under actual conditions should be performed. WHEATON accepts no responsibility for the accuracy of this data or for any consequences resulting from its use.

> 192

Technical Data